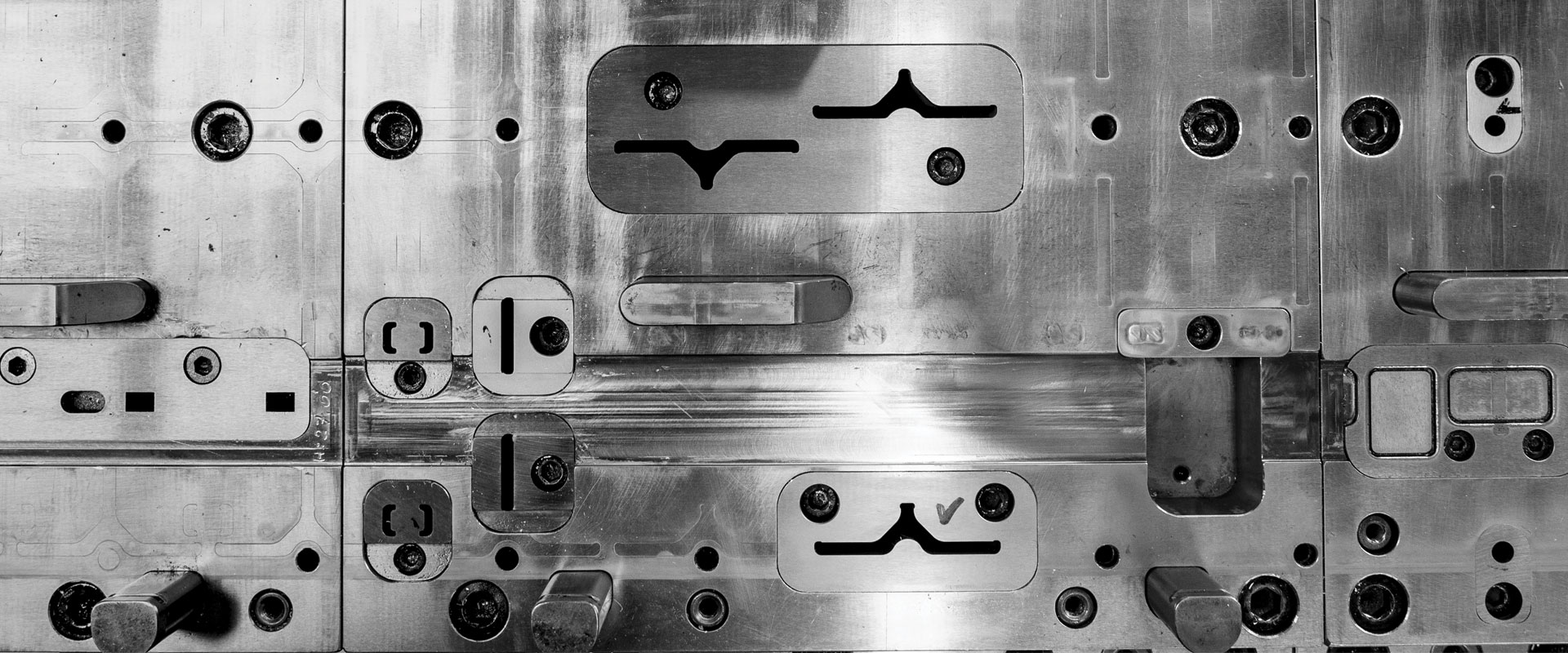

STAMP-FER has a modern and advanced mould making department.

It is possible to make progressive moulds, transfer, manual recovery, deep drawing or assembly of any size or type. Thanks to the appropriate technology and highly qualified staff, we have designed and manufactured efficient and reliable moulds of all complexity.

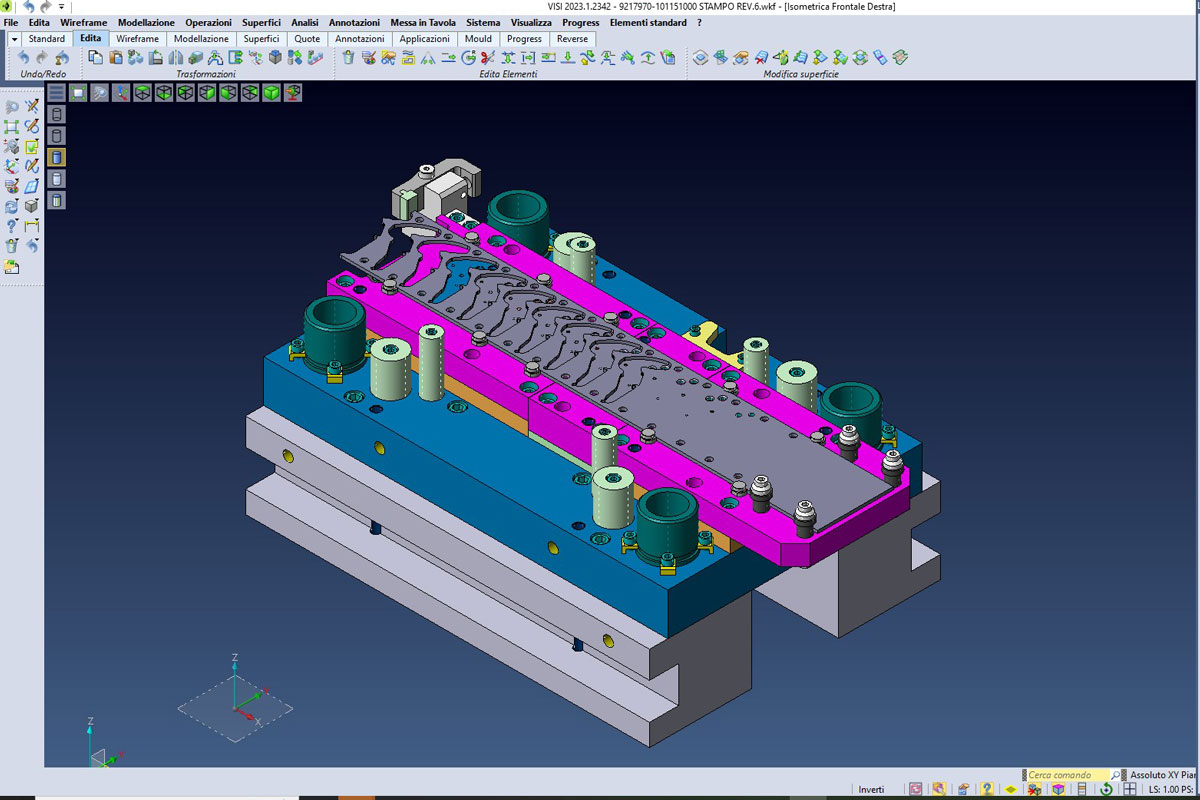

Mould making department:

- Wire EDM Sodick with worktop 600×400

- Mitshubishi wire EDM with worktop 500×300

- Vertical Machining Center Model She-Hong PRO 1000AG X 1000 Y 600 Z 630 with Mitsubishi M730XP control

- Doosan MYNX 7500/50-II” machining centre with worktops 1525x625x770

- Mazak work center worktops 500×300